Win an iPad at Ozwater 2024!*

Heading to Melbourne to visit the Ozwater 2024 trade show? Make sure to come and visit stand F27 to hear about Metroid Electrical Engineering’s capabilities and to enter our competition

Trusted Expertise.

100% Built In-house.

Compliance Guaranteed.

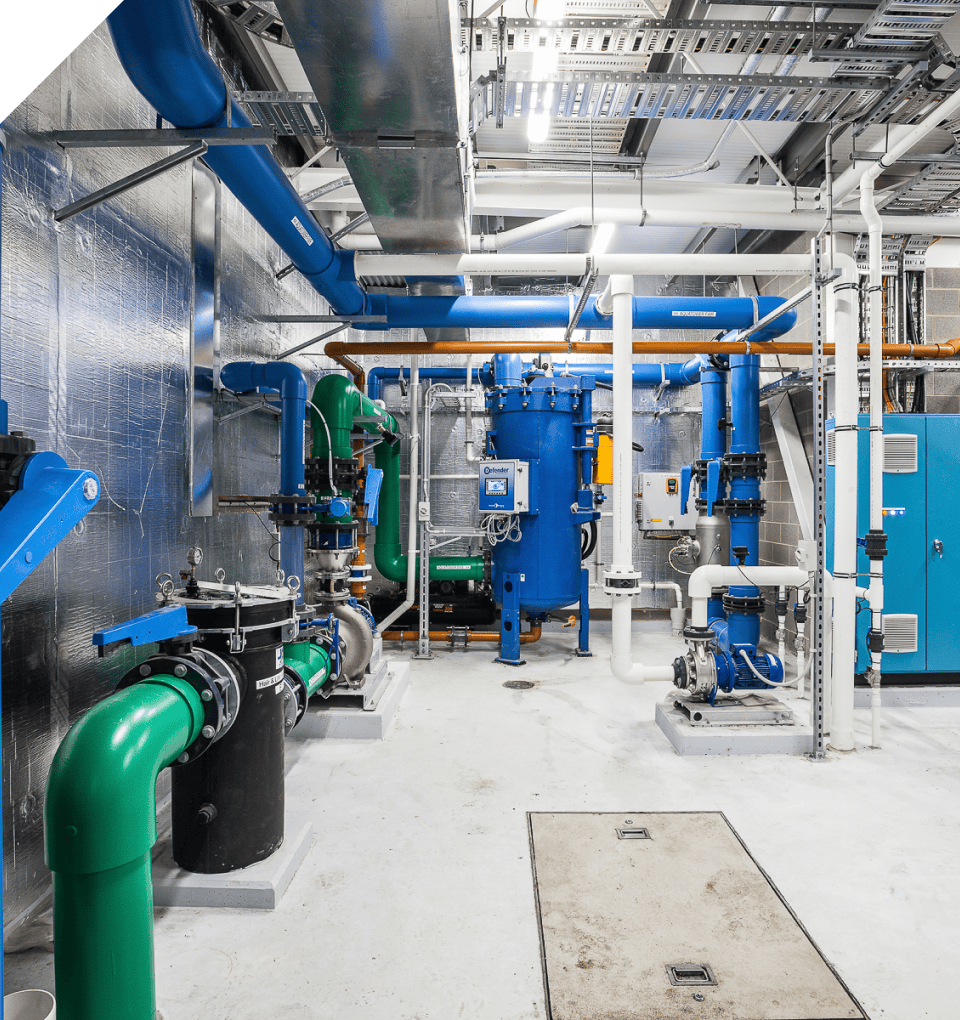

Coordinating the electrical scope for industrial process equipment can be challenging. Dealing with engineering headaches, missed deadlines and quality issues after delivery can derail your entire project, impacting costs, timelines, and your company’s reputation.

However, it doesn’t have to be this way. Here at Metroid we proudly stand for Aussie-made quality and compliance, engineering expertise and manufacturing know-how.

Wealth of experience: Metroid has over 15 years of experience building high-quality electrical control systems. We have completed over 2,000 projects in the past 10 years and programmed over 600 systems in the last five years alone across every major brand. We have the know-how to tackle any technical challenge.

Qualified engineers: Our team of 25+ qualified engineers are highly experienced in all facets of switchboard and automation engineering including design, engineering calculations, PLC/HMI/SCADA programming, tech support and onsite commissioning.

Generations of electrical engineering expertise: Electrical engineering has been our passion for five generations, and we'd love to help you solve your complex industrial control challenges. Show us your requirements, and we’ll engineer a solution.

Custom engineered and built in-house: Other electrical switchboard manufacturers often outsource one or more aspects of design, production or PLC programming. In contrast, Metroid has complete control over the entire process. From design and fabrication to programming, testing, and commissioning, every aspect is handled by our team. This ensures consistent quality, minimised risk of errors, and faster turnaround times.

Factory Acceptance Testing: We perform thorough live Factory Acceptance Testing including uploading of all PLC & HMI programs, greatly streamlining the commissioning process.

ISO9001 certified: We take quality and compliance very seriously. Quality checks are built into the entire engineering and build process with a comprehensive live factory test of hardware and software.

Compliance Assured: We have years of experience ensuring compliance with stringent end-client specifications for critical infrastructure projects and offer AS61439-compliant switchboard options, giving you peace of mind.

Industries

Our Process

Metroid Electrical Engineering handles the entire process from design, manufacture, programming, testing, commissioning and support.

Testimonials

Heading to Melbourne to visit the Ozwater 2024 trade show? Make sure to come and visit stand F27 to hear about Metroid Electrical Engineering’s capabilities and to enter our competition

Onsite Commissioning From metropolitan Sydney to the Pilbara, Adelaide to Central Queensland, our experienced engineers have ‘been there, commissioned that’. We’re available for attendance onsite anywhere in Australia and our

We will always conduct a full functional test in our workshop to eliminate any bugs and ensure your system performs exactly to your functional description. This allows straightforward installation by your preferred

Choose Metroid as your electrical engineering partner.